Ultrsound measurement

Non-destructive measurement of structures and defects in the structure

Description

The device consists of a transmitter-receiver unit with of 24 point-contact probes which are assembled in a transmitting and receiving part, each with 12 probes. The middle frequency is 55 kHz. Concrete components can be examined up to a thickness of about 0.7 m (depending on the particular conditions).

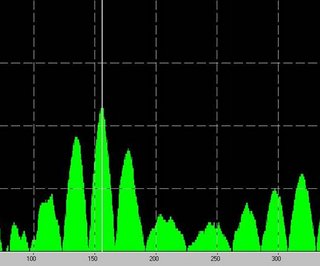

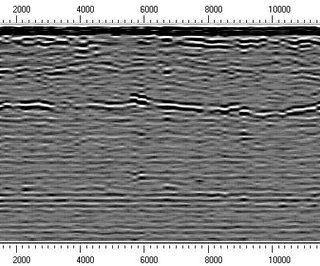

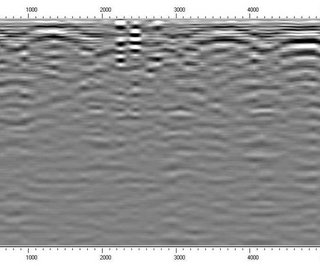

The battery-powered control unit produces a transmitter pulse, receives and stores the received pulses and displays them as an A, B or C scan. An A scan is a point scan, a B scan linear, and a C scan a two-dimensional ultrasound measurement. The depth (in mm) of the reflecting layers may be read after entering the transversal wave velocity (wave velocity calibrated on site) into the device.

The main issues for use on the structure are the following:

- Thickness measurement and determination of the element geometry with access from one side

- Localization and concrete cover of structural elements

- Localization of delaminations and voids (coatings, multi-layer systems, screed)

- Localization of injection defects in the ducts (prestressed concrete structures)

- Localization of compaction defects, in particular around the ducts.

Manufacturer / Device type

Acoustic Control Systems Ltd. / A1220 Monolith

Qualifications

Prof. Dr.-Ing. Christian Sodeikat and Dipl.-Ing. Philipp Obermeier are certified as group leaders according to the guideline for the non-destructive examination of tunnel linings (RI-ZFP-TU) with the ultrasonic device A1220 Monolith (device number 104021) of Acoustic Control Systems.