3D Printing / Additive Manufacturing

Consulting on process and material technological aspects, consulting during structural design and construction, building authority approvals

Consulting on process and material technological aspects, consulting during structural design and construction, building authority approvals

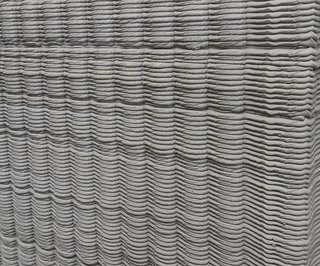

3D printing or additive manufacturing is a new construction technique that enables the production of (design) elements for interior and exterior use, components and structures (made of concrete, but also other materials) in a layered construction process. Besides the high degree of automation, this construction technique is characterized by the fact that no formwork or moulds are required. This allows a much greater freedom of form and design compared to conventional production techniques. However, there are usually no technical building regulations and no generally accepted rules of building and construction for the construction product, the construction method and the construction types.

Our services include:

- General consulting on process technology (e.g. selection of a printing process from the depositing and particle-bed based techniques)

- Consulting on material and concrete technology (e.g. selection / development of applicable materials such as concrete, clay or other mineral / (an-)organic binder-particle-bed-systems for 3D printing)

- Planning and development of test concepts for the determination of characteristic material and component properties

- Consulting during structural design and construction (e.g. design proposals according to the partly direction-dependent material properties of 3D-printed components, support during construction)

- Expert advice and support with building authority approvals and development of corresponding concepts.

Projects

Publications

Weger, D.:

Additive manufacturing of concrete structures by Selective Paste Intrusion – SPI / Additive Fertigung von Betonstrukturen mit der Selective Paste Intrusion – SPI (in German).

Dissertation, TUM, München, 2020.

Weger, D.; Baier, D.; Straßer, A.; Prottung, S.; Kränkel, T.; Bachmann, A.; Gehlen, C.; Zäh, M.:

Reinforced Particle-bed Printing by Combination of the Selective Paste Intrusion Method with Wire and Arc Additive Manufacturing – A First Feasibility Study

RILEM 2nd International Conference on Concrete and Digital Fabricaton. Eindhoven, 2020.

Lowke, D.; Talke, D.; Dressler, I.; Weger, D.; Gehlen, C.; Ostertag, C.; Rael, R.:

Particle-bed 3D-Printing by Selective Cement Activation – Applications, material and process technology.

Cement and Concrete Research, 2020.

Matthäus, C.; Weger, D.; Kränkel; T.; Gehlen, C.:

Effect of Thixotropy Enhancing Agents on Extrudability of Lightweight Concrete.

HiPerMat, Kassel, 2020.

Weger, D.; Gehlen, C.; Lowke, D.:

3D Concrete Printing / 3D-Betondrucken (in German).

Beiträge zur 6. DAfStb-Jahrestagung mit 59. Forschungskolloquium, Deutscher Ausschuss für Stahlbeton e.V., 2018, p.25-35.

Lowke, D.; Dini, E.; Perrot, A.; Weger, D.; Gehlen, C.; Dillenburger B.:

Particle-bed 3D printing in concrete construction – Possibilities and challenges.

Cement and Concrete Research, 2018.